The food production and packaging sector requires, due to the sensitivity of the environment and level of regulation, specific materials and solutions.

LEP’s product portfolio includes a range of materials specifically developed for food contact.

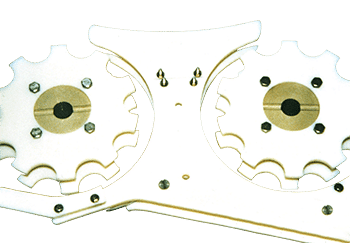

Our solutions aim at reducing maintenance costs and increase productivity in packaging equipment, also for non-food goods or pharmaceuticals.

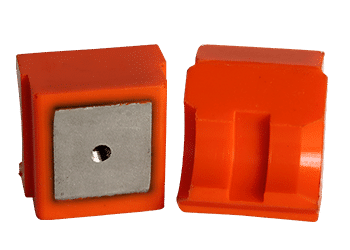

- Food compliant material formulation shorten certification time for installation and offer safety in design

- Improved productivity and product life time

- Reduced material friction and wear

- Self-lubricating formulations lower equipment maintenance costs

- Better design capabilities and higher level of automation possible as a result of low material coefficient of linear thermal expansion (CLTE) and tighter tolerances

- Special formulations, e.g. 3-A Sanitary-Dairy compliant materials allow higher shelf time of food stuff by providing lower level of contamination

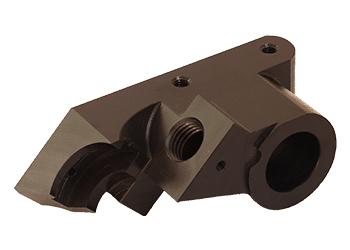

The creation and introduction of the new “Food Grade” material family is based on Quadrant’s migration limit tests and offers customers not only time savings on their application specific testing, but also the advantage of traceability along the entire value chain and control of the production process following Good Manufacturing Practice (GMP).

It also ensures maximum hygiene and non-contamination of food stuff that comes into contact with Quadrant’s materials.

Food compliancy certificates can be issued for the chosen products.