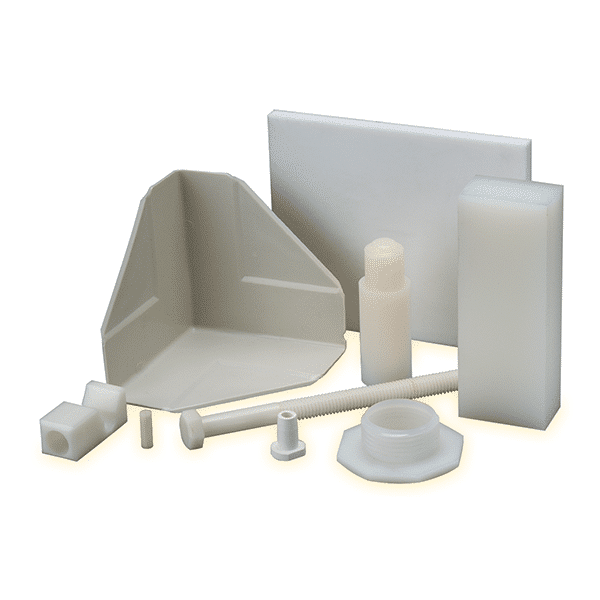

abs (acrylonitrile butadiene styrene) is an easily-machined, soft cream coloured plastic with a low melt point (120°C). It is easily thermoformed and has outstanding reproduction of mould detail. Extruded abs sheet can be easily heat-formed to produce tough, durable and rigid components by using any conventional thermoplastic sheet-forming equipment.

abs is easily machined to close tolerances and may be turned, bored, drilled, sheared and routed using high-speed and carbide-tipped tools. It can also be machine-finished by filing, grinding, sanding, buffing and polishing. Excellent impact strength makes abs ideal for fabrication, and it also possesses good chemical and stress-cracking resistance to many salt solutions, alkalis, mineral acids and oils.

abs is solvent cementable and has the ability to weld easily. It is one of the few non-metallic materials that can, under certain conditions, be readily electroplated.

Temperature range: -15°C to +60°C

Benefits

- High mechanical toughness and stiffness

- Easily thermoformed

- Good machining properties

- High impact strength

- Easily fabricated and formed

- Solvent cementable

Applications

- Fabricated components

- Hammer heads, handles

- Refrigeration linings

- Low rotation and high impact applications

- Suitcases and luggage

- Machine housings