acetal–U is a polyoxymethylene copolymer, to which approximately 10% ultra-high molecular weight polyethylene has been added.

This addition of uhmwpe works like a dry film lubricant, and has significantly better dry and emergency running in the case of a machine breakdown with regard to non-modified polyoxymethylene.

The co-efficient of friction to steel of 0.19 is significantly lower than that of other thermoplastics (standard acetal 0.3- 0.4 / 6SA nylon 0.25-0.4).

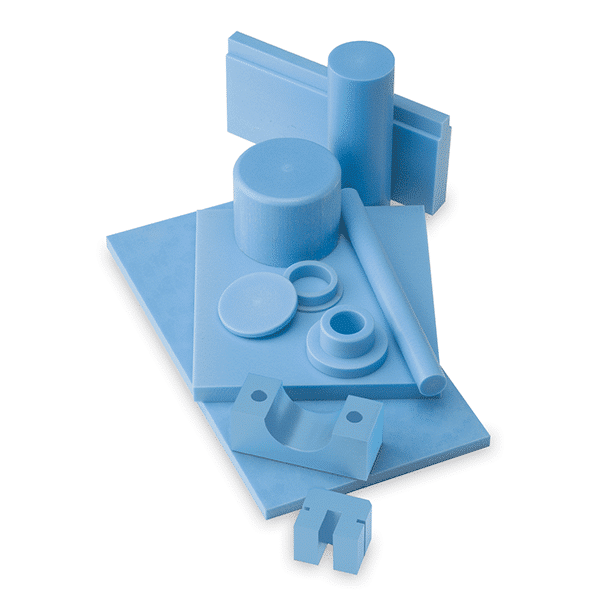

acetal-U is therefore very suited to the manufacture of bearing bushes and sliding plates.

The uhmwpe addition gives lower noise and self-lubrication. The extremely low absorption of water of 0.14% provides an increased dimensional stability. Machine components made from acetal-U are very resistant to wear and have a high working life.

acetal-U is manufactured in accordance with the BGA and FDA guidelines in its composition and can therefore be used in the food sector.

acetal-U is light blue in colour, and other colours are available on request.

Temperature range: -40ºC to +90ºC

(-40°C to +85°C in water)

Benefits

- Very high wear resistance

- Optimum slide properties

- High impact resistance

- Ideal in wet environments

- Suitable for food contact

- Increased dimensional stability

Applications

- Close tolerance and intricate machine components

- Bushes, sliding plates

- CIP Equipment

- Spindle bearings

- Lightly loaded gears