Nylatron® GS and GSM are filled nylons which have stiffer, harder and dimensionally more stable properties than unmodified nylons. The addition of MoS2 (molybdenum disulphide) creates a strong crystalline structure which enhances bearing and wear behaviour, without impairing the inherent impact and fatigue resistance of cast nylons.

Nylatron® GS and GSM are self-lubricating, quiet in operation and their lightness contributes to low inertia, which is often a factor under stop/start conditions. They are easily machined, have good load-bearing capabilities and their low co-efficient of friction makes them ideal for many bearing applications. MoS2-filled Nylatron® GS is also available in profile and strip form to provide an economic solution for heavy wear and load situations.

Temperature range:

Nylatron® GS: -20°C to +95°C (-20°C to +70°C in water)

Nylatron® GSM: -30°C to +105°C (-30°C to +70°C in water)

Benefits

- Good load bearing

- Good sliding properties

- Low co-efficient of friction

- High impact resistance

- Self-lubricating

- Excellent wear resistance

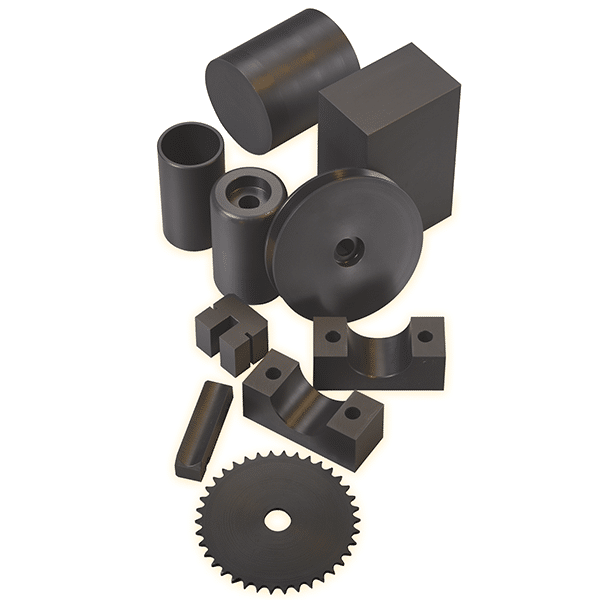

Applications

- Gears and sprockets

- Support and guide wheels

- Conveyor rollers

- Bearings and sheaves

- Wear pads and strips