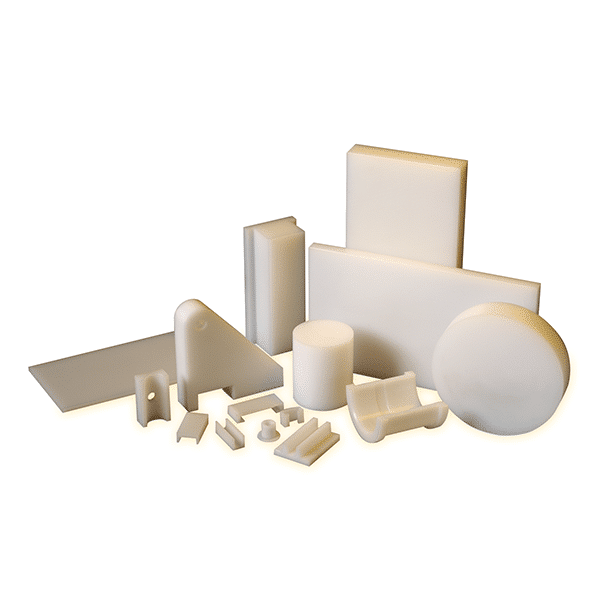

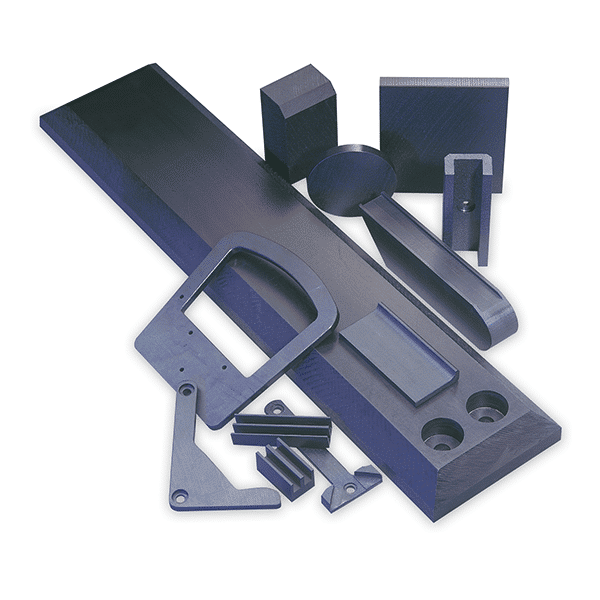

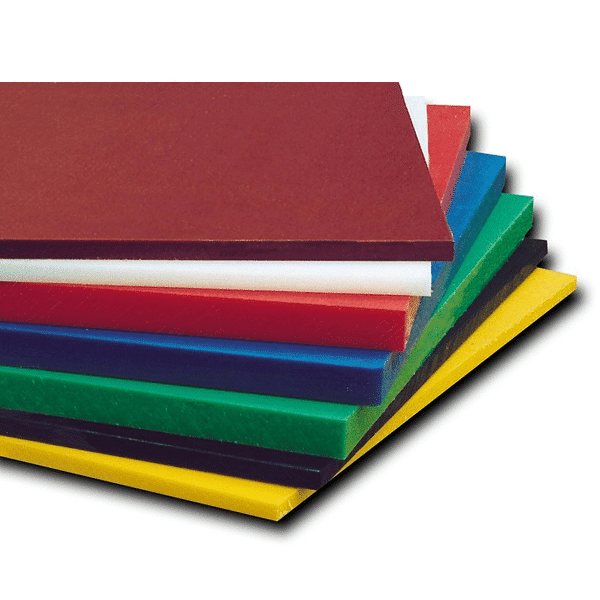

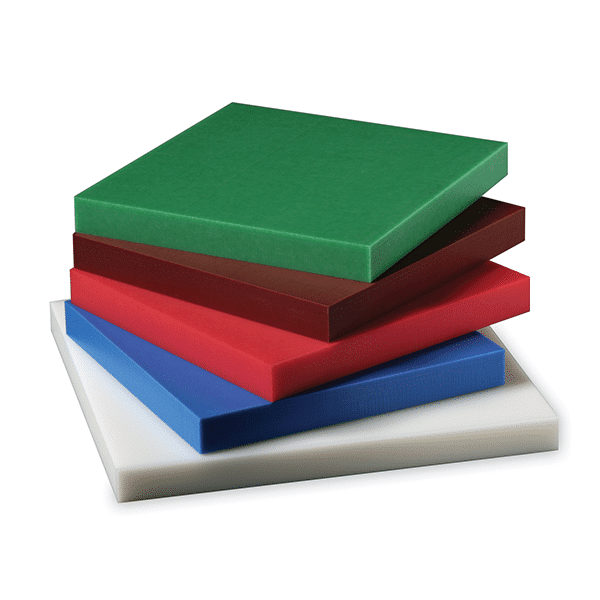

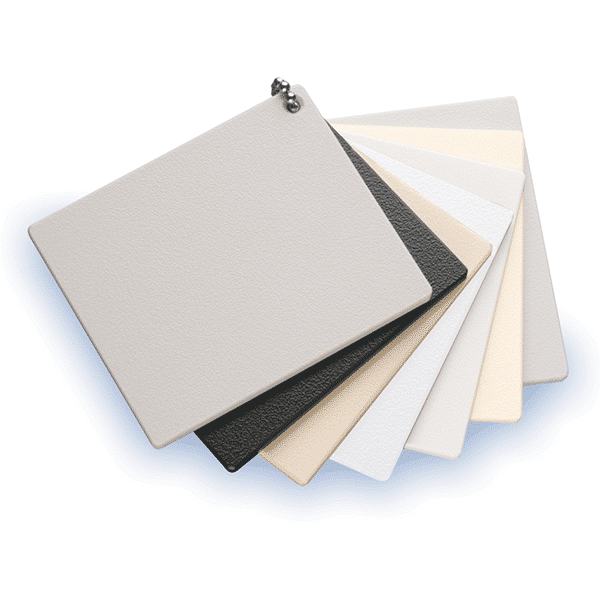

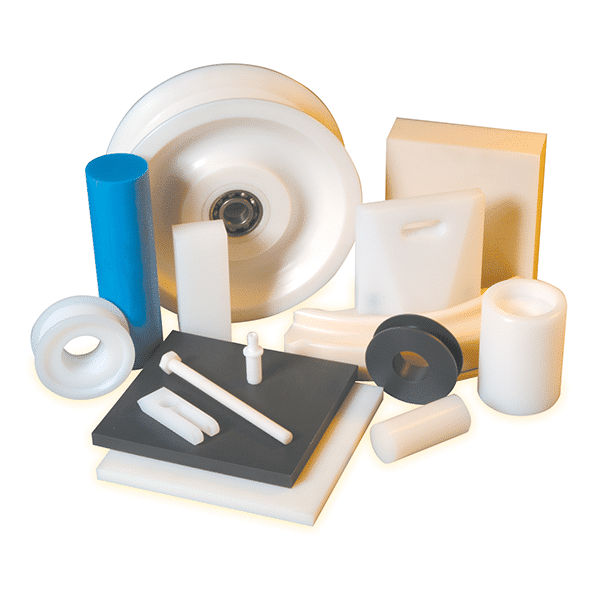

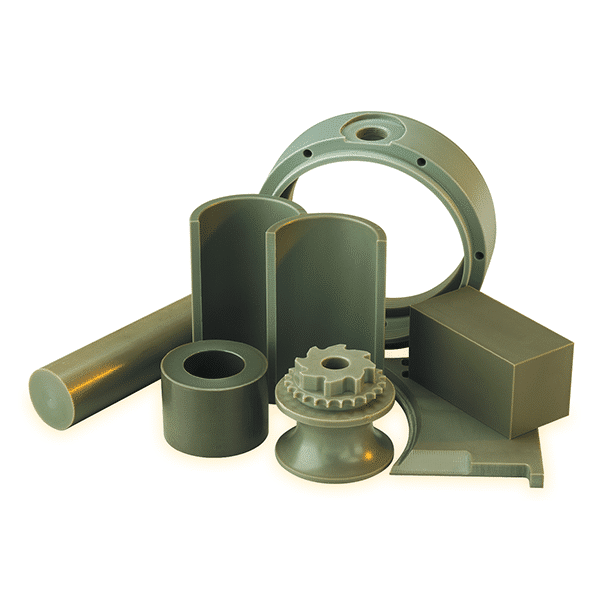

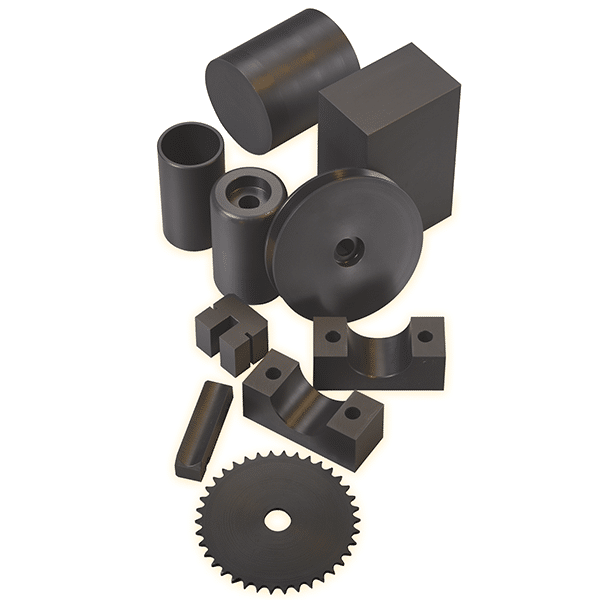

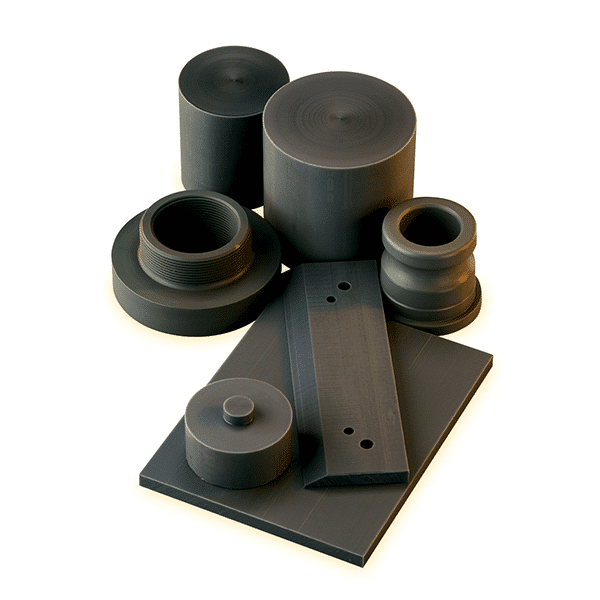

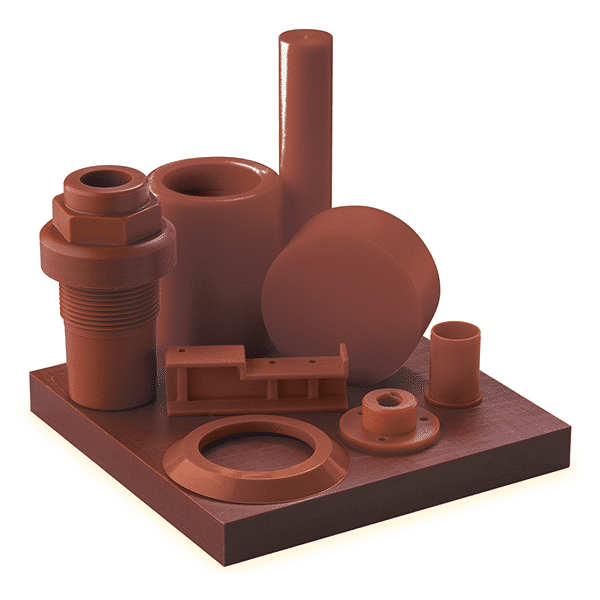

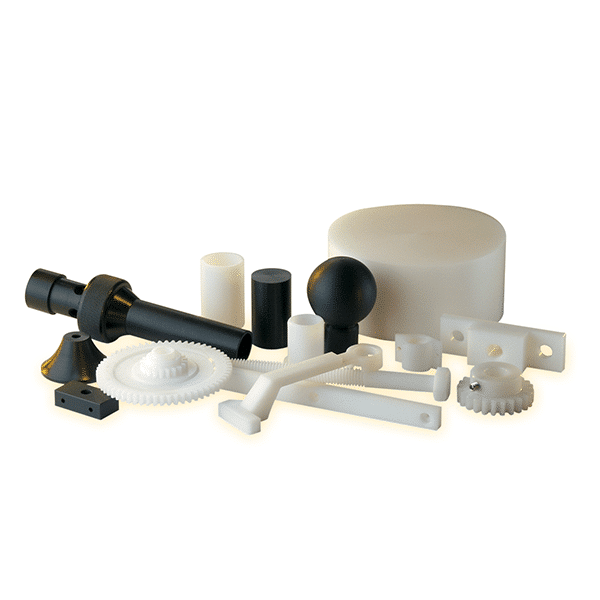

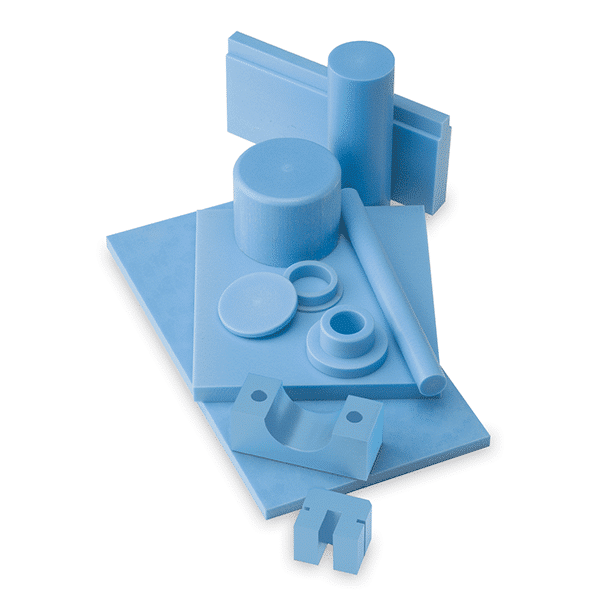

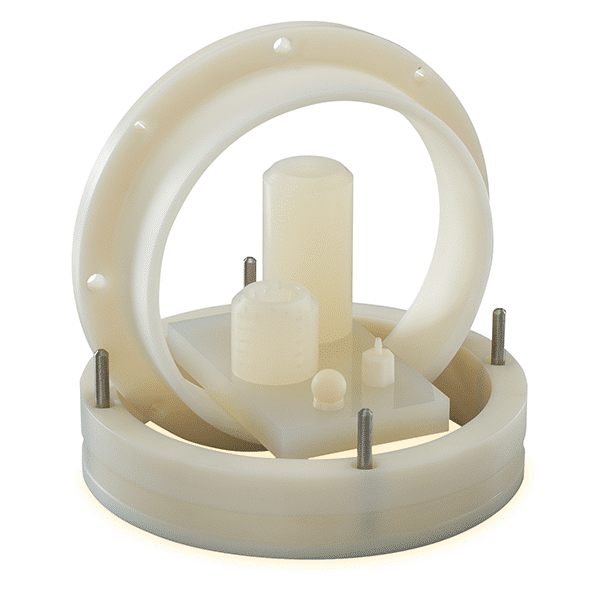

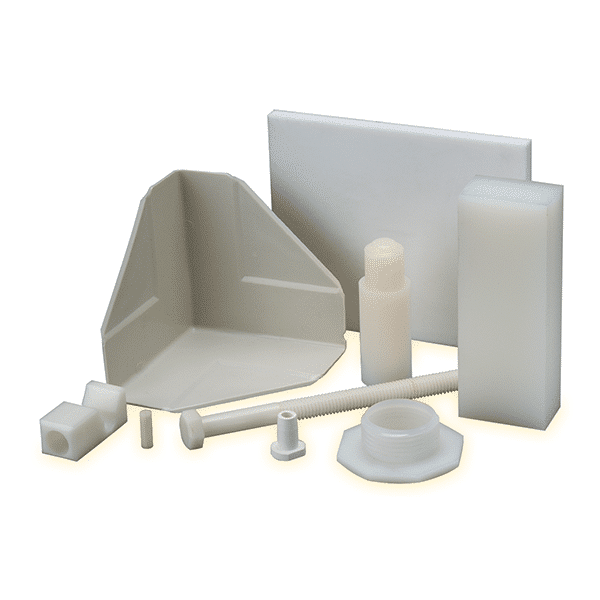

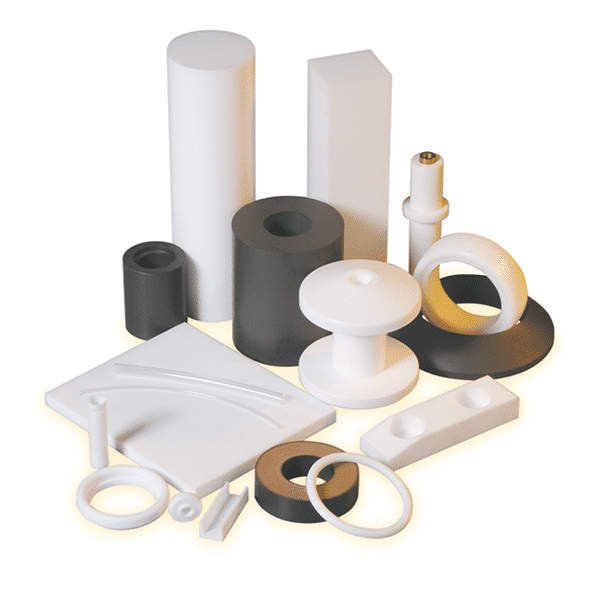

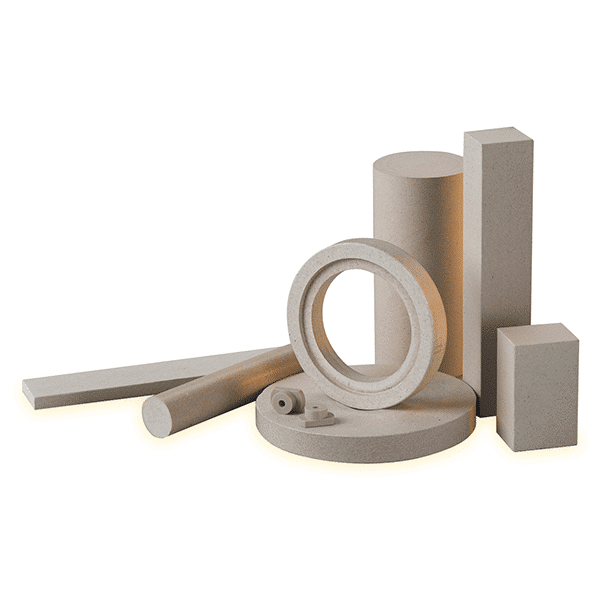

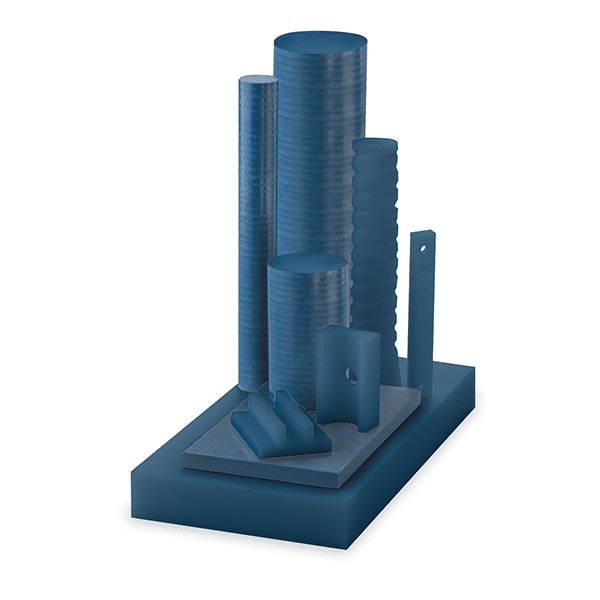

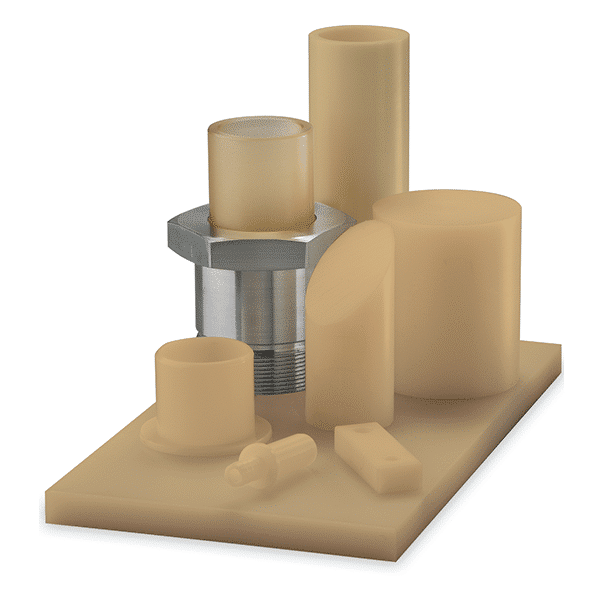

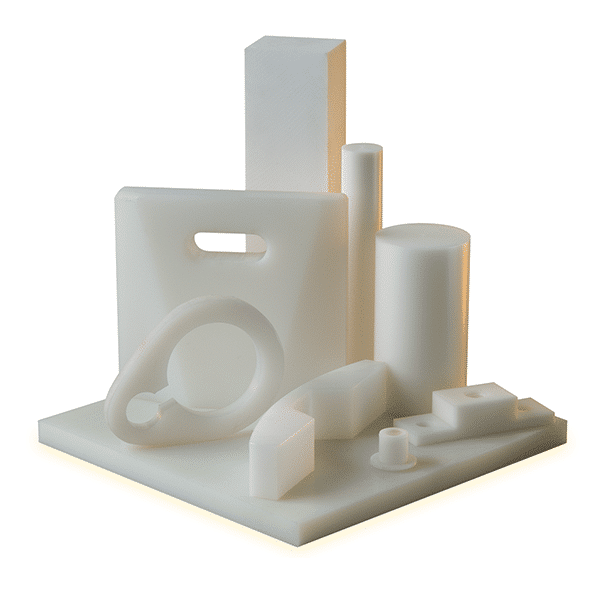

Engineering plastics are increasingly replacing traditional materials such as bronze, stainless steel, cast iron and ceramics. Their ease of fabrication, self-lubricating properties and the range of size and shapes available make thermoplastics the ideal choice for specific bearing and wear applications, as well as structural components.

Engineering plastics offer improved performance and cost-effectiveness. They are typically specified in a wide range of industrial applications, from semi-conductor processing equipment materials to heavy equipment wear parts to food-processing industry components.

Typical physical properties include good chemical and wear resistance, heat and abrasion resistance, dimensional stability and tensile strength.

They also have the ability to reduce weight and noise, insulate and isolate both thermally and electrically, eliminate corrosion and operate successfully in unlubricated environments.

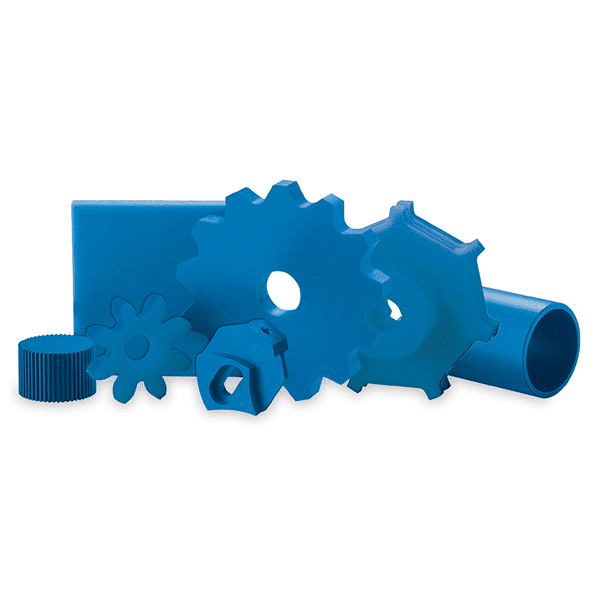

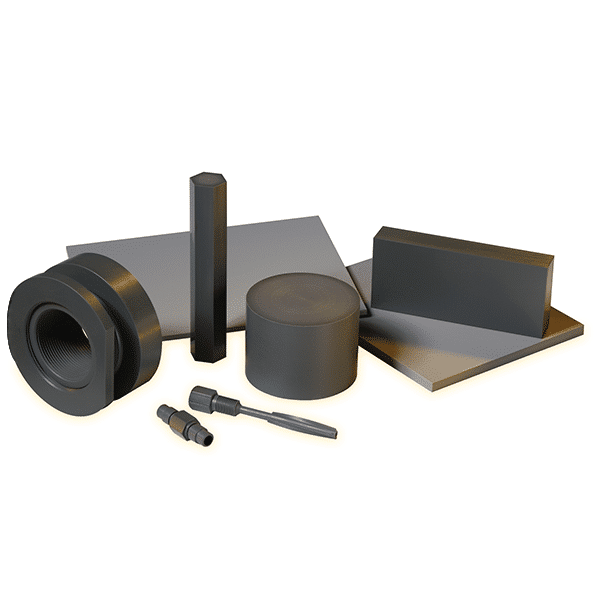

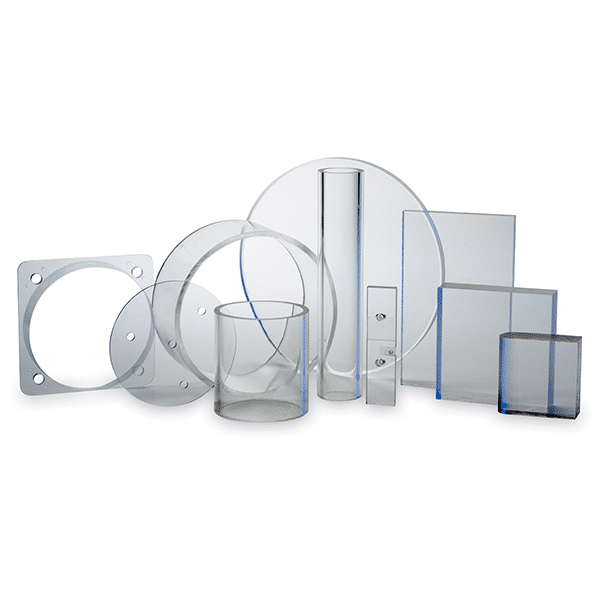

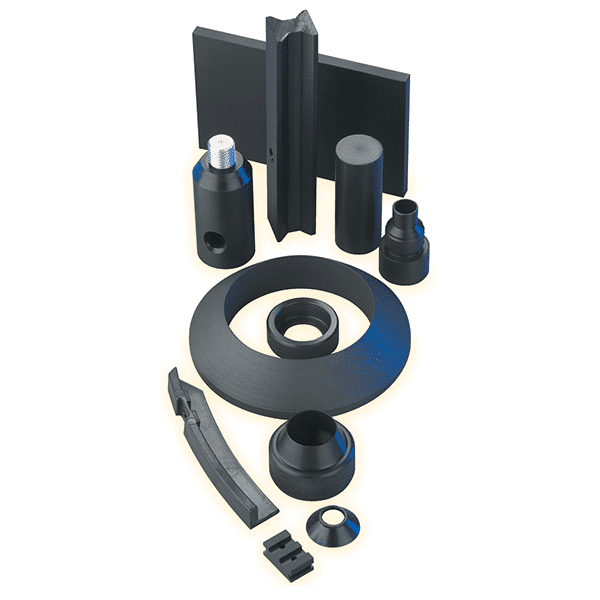

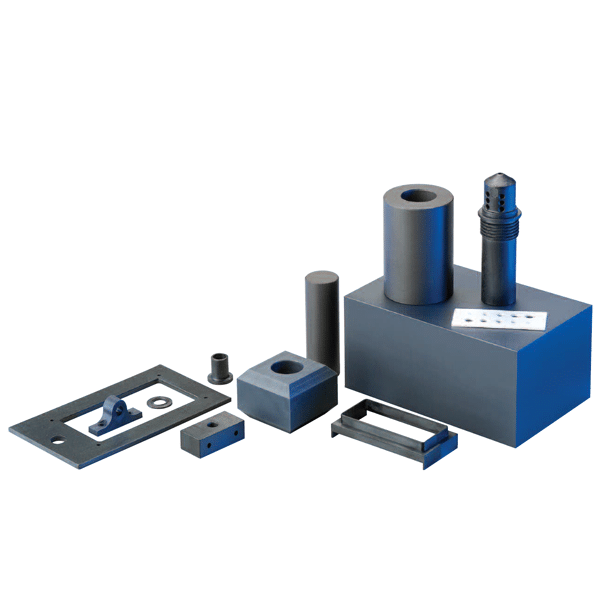

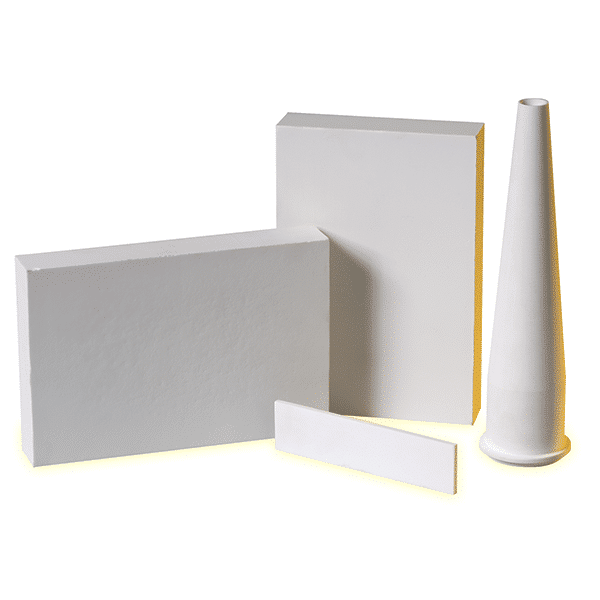

HIGH PERFORMANCE PLASTICS

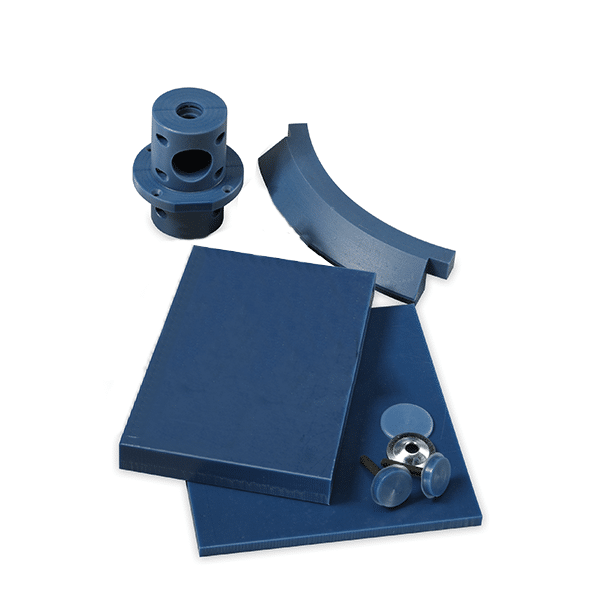

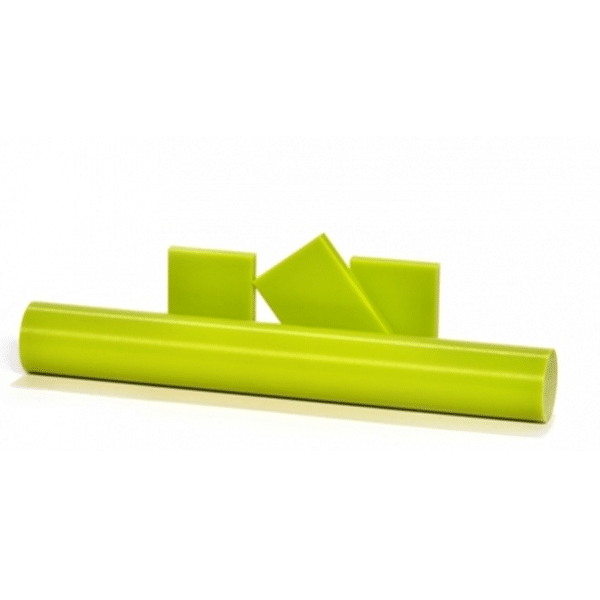

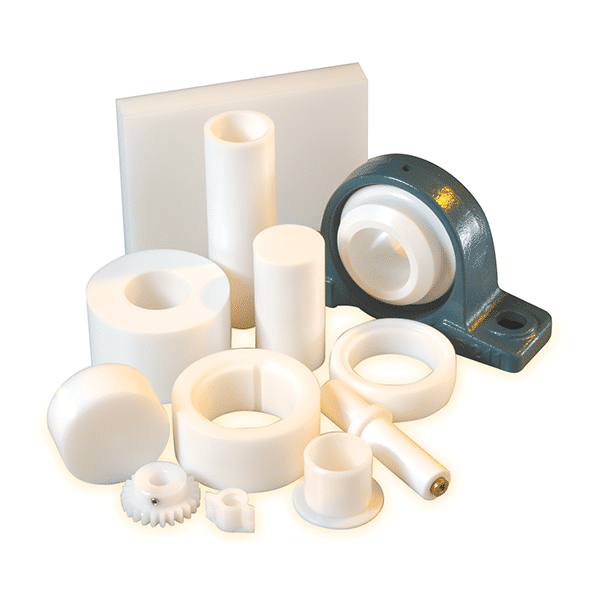

This specialised group of thermoplastics exhibit a range of unique properties and characteristics which far exceed those of standard engineering plastics.

They are normally specified for demanding industrial applications, where a high performance thermoplastic will perform successfully under the most extreme conditions of temperature, chemical environment, stress, wear, radiation and electrical usage.

One of the main characteristics of high Performance materials is their ability to perform continuously at very high maximum allowable service temperatures in air (over 300°C), exhibiting strength and hardness even at these temperatures.

Some formulations also meet the requirements of EU/FDA regulations concerning foodstuff contact. They are able to be specified for use in the medical, pharmaceutical and food processing industries.

Their unique combination of high mechanical and dielectric properties, superior chemical resistance, coupled with a very low co-efficient of friction and high PV limits make these thermoplastics ideally suited to many applications, including packaging, aerospace, automotive and electronic.